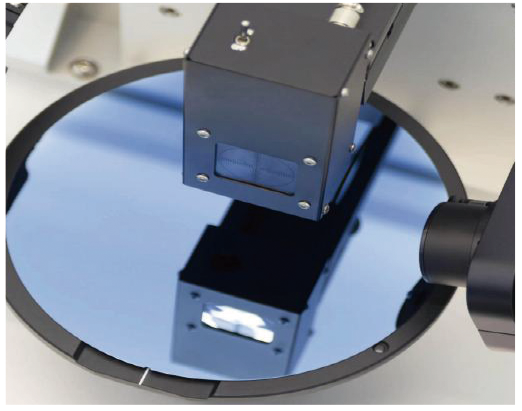

CMP special silica sol for grinding and polishing

#Application ·2025-08-21 17:12:05

CMP grinding and polishing dedicated silica sol is a key material used in the chemical mechanical polishing (CMP) process, formed by dispersing nano-scale silica particles in water. Here is its detailed introduction:

- Characteristics

- The particle size is precise and evenly distributed: The particle size of silica sol is usually between 10 and 150 nanometers. Some high-end products can control the D50 (median particle size) fluctuation within ±2 nanometers. The uniform particle size distribution helps to achieve a consistent polishing effect.

- High sphericity: The particles are in regular spherical shapes, which can reduce scratches on the workpiece surface during the polishing process. It is especially suitable for polishing materials with extremely high surface quality requirements, such as semiconductor silicon wafers.

- Moderate hardness: Its hardness is similar to that of materials such as silicon wafers. As a soft abrasive, it can effectively remove materials during polishing without causing excessive damage to the surface of the workpiece.

- High dispersibility: The surface of silica sol particles often adsorbs OH - and becomes negatively charged. Through electrostatic repulsion, it maintains good dispersion stability, is not prone to aggregation or sedimentation, and can be uniformly dispersed in the polishing liquid, ensuring the uniformity of polishing.

- Good chemical stability: During the polishing process, it is not prone to chemical reactions with silicon wafers and other workpieces, avoiding surface corrosion or damage. At the same time, a uniform silicon dioxide protective film can be formed on the surface of the workpiece after polishing, improving the weather resistance and stability of the workpiece.

- Its role in CMP

- It offers highly efficient grinding capabilities: Nano-sized silica particles are used as abrasives. Through the combined effect of physical grinding and chemical corrosion, it can effectively remove tiny protrusions and scratches on the surface of workpieces, achieving a high polishing efficiency. The material removal rate can reach 0.9-1.2 microns per minute.

- Ensure surface quality: Due to its fine and uniform particle size, it can achieve uniform polishing of all areas of the workpiece surface, reduce surface roughness, and the surface flatness of the polished wafer is high, with the Ra value controllable below 0.2nm and the TTV value less than 3μm, meeting the strict requirements for surface quality in high-end fields such as chip manufacturing.

- Regulating the polishing process: According to different polishing requirements, the polishing rate and effect can be controlled by adjusting parameters such as the concentration of silica sol, pH value, and temperature to meet the needs of different materials and processes.

- Advantage

- Enhancing production efficiency: The application of silica sol can shorten polishing time. For instance, the process of wafer planarization, which traditionally takes tens of hours through mechanical polishing, can be reduced to 3 to 5 hours with the use of silica sol. Meanwhile, data from a leading wafer factory shows that its application has increased the production capacity of a single CMP by 40%.

- Cost reduction: Silica sol polishing liquid has good chemical stability, is not prone to deterioration, and can be recycled 5 to 8 times. Moreover, the price of domestic silica sol is only one-third of that of imported products, which promotes a 25% reduction in the single cost of the CMP process.

- Good environmental performance: Silica sol is non-toxic and harmless, and its VOCs emissions are only 1/5 of those of traditional organic polishing liquids, meeting environmental protection requirements.

Tags:

Prev:Not Data