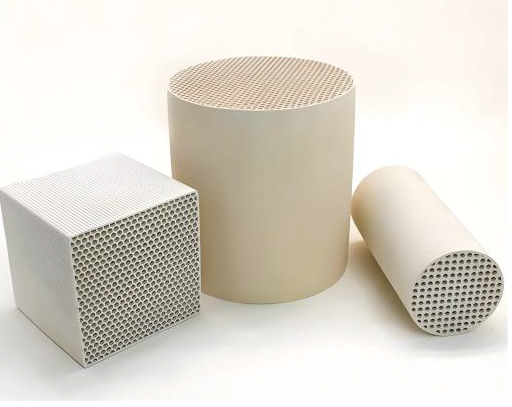

Silica sol for special ceramics

#Application ·2025-08-21 16:57:20

Special ceramic-specific silica sol is a colloidal solution mainly composed of nano-scale silica and plays a significant role in the production of special ceramics. Here is its detailed introduction:

- Characteristics

- Controllable and uniform particle size: The particle size of special ceramic-specific silica sol is usually at the nanometer level. According to the requirements of different ceramic production processes, the particle size can be precisely controlled, and the distribution is uniform. It can be evenly dispersed in ceramic materials, ensuring the consistency of ceramic performance.

- Extremely low impurity content: It features extremely high purity and very low impurity content, which can prevent impurities from adversely affecting the performance of ceramics and ensure the high quality of special ceramics.

- Good dispersibility and stability: The surface of the silica particles in silica sol has been specially treated, which has good dispersibility. During storage and use, it is not easy to coagulate and precipitate, and can maintain a stable colloidal state for a long time, which is convenient for processing and application in the ceramic production process.

- High adhesiveness: When the moisture of silica sol evaporates, the colloidal particles can firmly adhere to the surface of ceramic particles, forming a silicon-oxygen bond between the particles. It is an excellent binder that can enhance the strength and formability of ceramic bodies.

- Excellent high-temperature resistance: It has outstanding fire-resistant and thermal insulation performance, capable of withstanding temperatures of 1500-1600℃ without failure, and can meet the requirements of special ceramics during high-temperature firing processes.

- Its role in the production of special ceramics

- Enhancing the compactness of ceramic bodies: The nanoparticles of silica sol can fill the tiny pores between ceramic particles, reducing porosity and making the structure of the ceramic body more compact, thereby improving the strength, hardness and wear resistance of ceramics and other properties.

- Improving the mechanical strength of ceramics: As a binder, silica sol can enhance the bonding force between ceramic particles, increase the mechanical strength of the ceramic body, and make it less prone to cracking when subjected to external forces.

- Regulating the sintering performance of ceramics: Silica sol can promote the diffusion and reaction between particles during the sintering process of ceramics, lower the sintering temperature, shorten the sintering time, and at the same time improve the sintering quality of ceramics and reduce the occurrence of defects.

- Enhancing the corrosion resistance of ceramics: The characteristics of filling pores and forming a dense structure make ceramics more resistant to the erosion of acids, alkalis and other chemical substances, thereby improving the chemical stability of ceramics.

- Application field

- In the field of structural ceramics: It is used to manufacture high-performance ceramic cutting tools, ceramic bearings, ceramic molds, etc., to enhance the hardness, strength and wear resistance of ceramics and extend the service life of products.

- In the field of functional ceramics: In the production of electronic ceramics, optical ceramics, bioceramics and other functional ceramics, special ceramic silica sol can be used to improve the electrical properties, optical properties and biocompatibility of ceramics, such as in the manufacture of ceramic capacitors, ceramic sensors, artificial bones, etc.

- In the field of refractory ceramics: As a binder and reinforcing agent, it is used to prepare refractory ceramic fiber products, refractory ceramic cores, etc., to enhance the high-temperature resistance and thermal shock resistance of refractory ceramics.

Tags: